The attached table might be informative to show the involved factors of the light/small vehicles in my plan, compared to heavy/large vehicles.the principles that you want to apply should also be applicable to a small car, and should not depend upon heavy vehicles to work. This is not a criticism of your ideas for energy recovery, just a suggestion that the presentation of your ideas should not depend upon them being applied to large or heavy vehicles.

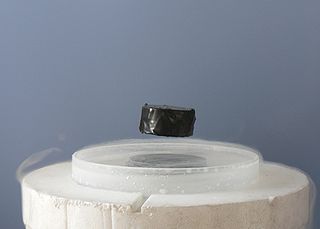

Much work can be done about the solenoids. Those suggested rails that confine the sliding magnets could be made by long carbon nanotubes (18.5 cm long, reported in 2009). The superconductivity property of carbon nanotubes is also required. Inspired by the magnetic levitation, because of superconductivity, like this image:As for the production of a vacuum in the solenoid tubes, this should be easily possible, and should not require an on-board vacuum pump. I envision the solenoids being sealed, possibly by welding or heat-sealing, depending upon the choice of material. I know from experience that a quite high vacuum will persist for several years, assuming the right materials, and method of sealing. Once sealed, they should be maintenance-free for quite a long time.

It is possible to make the solenoids very efficient. All of such solutions are achievable within the realm of current technology; for example, read these articles:

[ame="http://en.wikipedia.org/wiki/Magnetic_bearing"]Magnetic bearing - Wikipedia, the free encyclopedia[/ame]

[ame="http://en.wikipedia.org/wiki/Magnetic_levitation"]Magnetic levitation - Wikipedia, the free encyclopedia[/ame]

[ame="http://en.wikipedia.org/wiki/Technological_applications_of_superconductivity"]Technological applications of superconductivity - Wikipedia, the free encyclopedia[/ame]

Moreover, if a suitable vacuum could be built inside the solenoids, that would be highly effective. As an instance, the highest recorded speed of a magnetic levitation train is 581 km/h, achieved in Japan, but the lack of air resistance could permit vacuum tube trains to use little power and to move at extremely high speeds, up to 64008000 km/h. To compare these two cases, see the below articles:

[ame="http://en.wikipedia.org/wiki/Maglev_train"]Maglev - Wikipedia, the free encyclopedia[/ame]

[ame="http://en.wikipedia.org/wiki/Vactrain"]Vactrain - Wikipedia, the free encyclopedia[/ame]

Therefore, if we combine the technologies of magnetism and vacuum, I estimate the efficiency of +95% for the solenoids mechanism.

As you see, I'm not talking about the futuristic ideas, my plan works for today, but the expenses factor has the main role.

Reply With Quote

Reply With Quote